EN 10083-3: 2006 Steels for quenching and tempering. Technical delivery conditions for alloy steels

EN 10132-3: 2000 Cold rolled narrow steel strip for heat treatment. Technical delivery conditions. Steels for quenching and tempering

EN 10305-1: 2010 Steel tubes for precision applications. Seamless cold drawn tubes. Technical delivery conditions

EN 10269: 1999 Steels and nickel alloys for fasteners with specified elevated and/or low temperature properties

EN 10263-4: 2001 Steel rod, bars and wire for cold heading and cold extrusion. Technical delivery conditions for steels for quenching and tempering

EN 10250-3: 2000 Open steel die forgings for general engineering purposes. Alloy special steels

EN 10297-1: 2003 Seamless circular steel tubes for mechanical and general engineering purposes. Non-alloy and alloy steel tubes. Technical delivery conditions

Chemical composition

| Standard | Grade | C | Si | Mn | P | S | Cr |

| ASTM A29 | 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤ 0.035 | ≤ 0.04 | 0.8-1.1 |

| EN10083 | 42CrMo4 | 0.38-0.45 | ≤ 0.4 | 0.6-0.90 | ≤ 0.025 | ≤ 0.035 | 0.9-1.2 |

| 1.7225 | |||||||

| JIS G4105 | SCM440 | 0.38-0.43 | 0.15-0.35 | 0.6-0.85 | ≤ 0.035 | ≤ 0.04 | |

| GB 3077 | 42CrMo | 0.38-0.45 | 0.17-0.37 | 0.5-0.80 | ≤ 0.035 | ≤ 0.035 | |

| BS 970 | EN19 | 0.35-0.45 | 0.15-0.35 | 0.5-0.80 | ≤ 0.035 | ≤ 0.035 |

Equivalent Grades of Steel 30CrNiMo8(1.6580)

| EU | Germany | Japan | France | England | China | Russia | Inter |

| EN | DIN,WNr | JIS | AFNOR | BS | GB | GOST | ISO |

| 42CrMo4 | 42CrMo4 | SCM440H | 42CD4 | 708M40

CFS11 |

42CrMo | 42HM | 42CrMo4 |

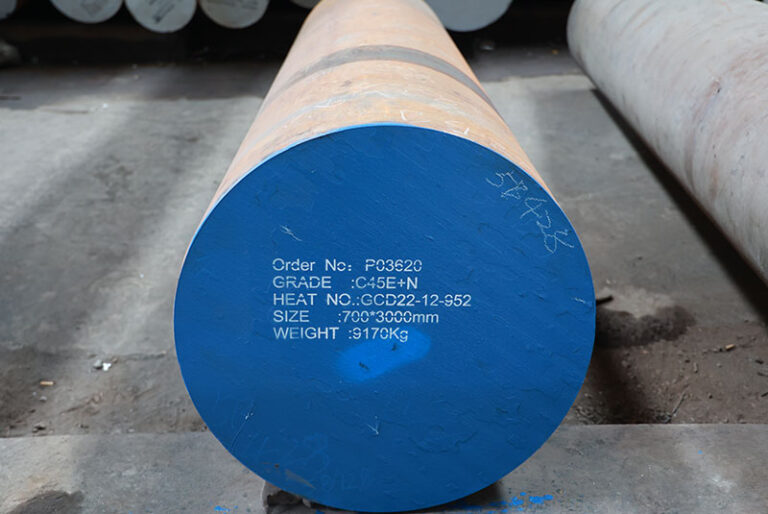

Description of Steel 42CrMo4(1.7225)

42CrMo4 material (1.7225 steel) is an European standard alloy steel, the delivery condition of this steel is mostly tempered and quenched, it has high strength, high toughness, good hardenability, temper brittleness, high fatigue limit, good impact resistance after quenching and tempering, and good low temperature impact toughness. This steel is suitable for the manufacture of large and medium-sized plastic molds requiring a certain degree of strength and toughness, transmission gears, rear axles, load-carrying connecting rods, spring clips and oil deep well drill pipe joints.

Size Tolerance

| Surface Finish | Size Tolerance | Length |

| Black For Forged condition | (0,+5mm) | Multiple Length/Fixed Length |

| Black For Rolled condition | (0,+1mm) | |

| Turned | (0,+3mm) |

Mechanical properties of Steel 42CrMo4(1.7225)

| Property | Specification |

|---|---|

| Yield Strength | Re > 500 MPa |

| Tensile Strength | Rm: 750-900 MPa |

| Elongation | A > 14% |

| Percent Reduction of Area | Z > 550% |

| Impact Energy | KV > 35 J |

| Heat Treatment Process | Temperature Range | Cooling Method |

|---|---|---|

| Normalizing | 850-880°C | Cooling in air |

| Soft Annealing | 680-720°C | Cooling in furnace |

| Stress Relieving | 450-650°C | Cooling in air |

| Hardening | 820-880°C | Oil or water quench |

| Tempering | 540-680°C | Cooling in air |

Reviews

There are no reviews yet.