EN 10277-5: 2008 Bright steel products. Technical delivery conditions. Steels for quenching and tempering

EN 10083-3: 2006 Steels for quenching and tempering. Technical delivery conditions for alloy steels

EN 10269: 1999 Steels and nickel alloys for fasteners with specified elevated and/or low temperature properties

EN 10263-4: 2001 Steel rod, bars and wire for cold heading and cold extrusion. Technical delivery conditions for steels for quenching and tempering

EN 10250-3: 2000 Open steel die forgings for general engineering purposes.

Alloy special steelsChemical composition

| Standard | Grade | C | Si | Mn | P | S | Cr |

| EN 10083 | 34CrNiMo6/DIN 1.6582 | 0.30-0.38 | ≤0.4 | 0.5-0.8 | ≤0.025 | ≤0.035 | 1.3-1.7 |

| EN 10250 | 0.30-0.38 | ≤0.4 | 0.5-0.8 | ≤0.035 | ≤0.035 | 1.3-1.7 | |

| SEW 550 | 0.30-0.38 | ≤0.4 | 0.4-0.7 | ≤0.035 | ≤0.035 | 1.4-1.7 | |

| DIN 17200 | 0.30-0.38 | ≤0.4 | 0.4-0.7 | ≤0.035 | ≤0.03 | 1.4-1.7 |

Equivalent Grades of Steel 34CrNiMo6(1.6582)

| EU | Germany | Japan | France | England | China | Russia | Inter |

| EN | DIN,WNr | JIS | AFNOR | BS | GB | GOST | ISO |

| 34CrNiMo6 | 34CrNiMo6 | SNCM447 | 35NCD6 | 817M40 | 34CrNi3Mo

34CrNiMo ZG34CrNiMo |

36KH2N2MFA

38KH2N2MA 40KHN2MA |

36CrNiMo6

|

Description of Steel 34CrNiMo6(1.6582)

EN 34CrNiMo6 Steel is an important alloy engineering steel grade as per BS EN 10083-3:2006. 34CrNim06 steel has high strength, high toughness and good hardenability. EN / DIN 34CrNiMo6 alloy steel has the stability of resistance to overheating, but the white sensitivity of 34CrNiM06 is high. It also has the temper brittleness, so the weldability of 34CrNiMo6 material is poor. The steel 34CrNiMo6 needs the high temperature preheating before welding in order to eliminate the stress after welding processing.

| Surface Finish | Size Tolerance | Length |

| Black For Forged condition | (0,+5 ~ +8mm) | Multiple Length/Fixed Length |

| Black For Rolled condition | (0,+1mm) | |

| Rough Turned | (0,+3mm) |

Mechanical properties of Steel 34CrNiMo6(1.6582)

Tensile Strength:min 800 N/mm2

Yield Strength:min. 600 N/mm2

Elongation:min.9 %(l)

Kv-Imapct value:min..35J (l)

Heat Treatment Conditions

+A Soft annealed/Soft annealing

+N Normalized/Normalizing

+QT Quenched and Tempered

+U Untreated

+SR Stress Relieved

Normalizing:850℃-880℃,Cool in air

Soft Annealing:680℃-720℃,Cooling 10℃ per hour in furnace,max. 248 HB

Quenching: 830-860 °C

Hardening:830 – 860°C,oil or polymer,840-850°C,water

Tempering:540°C – 680°C, cool in still air

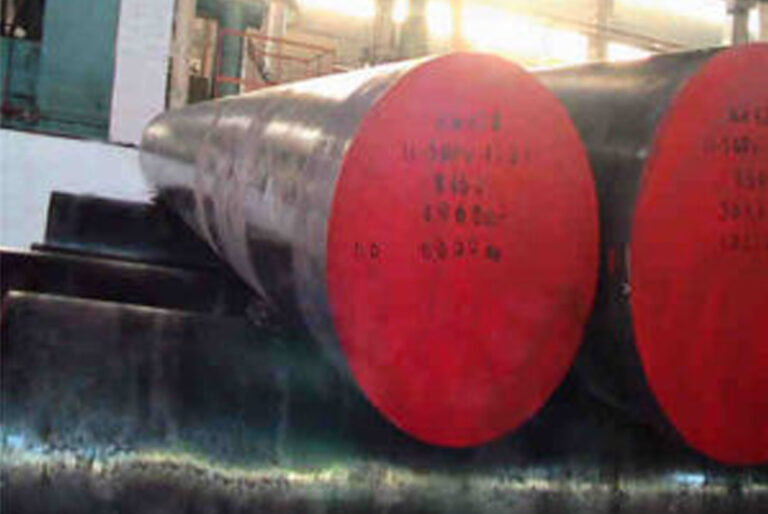

Drawn and hot-rolled bars, flat bars 34CrNiMo6, 1.6582

Forgings and forged bars in grade 34CrNiMo6, 1.6582

Reviews

There are no reviews yet.